ABOUT THE DIAMOND & CBN

Diamond is high resistant to wear and the most strong material in the world which consists of pure Carbon (C) .

It has characteristic that can supply of diamond tools in industrial market and developed synthetic diamond power.

CBN (Cubic Boron Nitride) is composed of Boron and Nitrogen that have similar structures.

CBN is more suitable element than diamond when grinding steel.

A. ABRASIVE TYPE

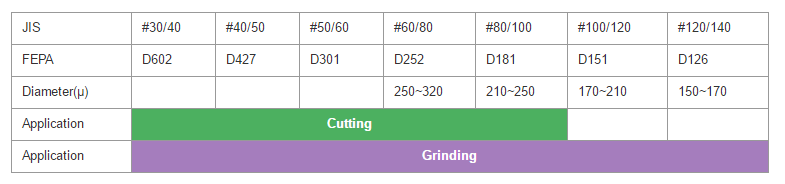

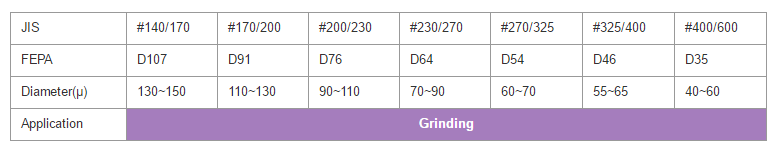

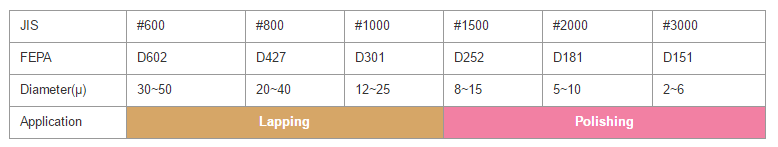

B. GRIT SIZE indicates the abrasive size on the Superabrasives wheel .

A higher grit number indicates a smaller abrasive grain and a finer abrasive product.

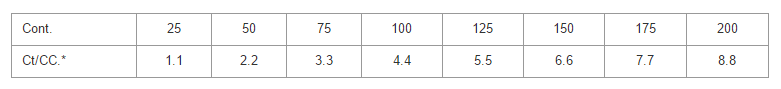

D. CONCENTRATION means how much abrasive is contained in a unit volume of the Superabrasives wheel.

E. Bond Type

Different bond has difference characteristic to choice with suitable working condition which will solve grinding problems efficiently

and economically.

B (Resin)

Resin bond is mainly composed of Phenolic or polyimid resin having thermo setting plastic.

Used widely in applied for hard materials such as tungsten carbide, high speed steels, ceramics, glass, silicon and sintered ferrous metals.

M (Metal)

Metal bond is usually binding material of metallic powders of tin, copper, iron, cobalt and etc.

It has excellent form-holding capability, wear & heat resistance, long tool life, high productive grinding

and cutting for brittle material such as glass, cermet, ferrite, quartz, silicon wafer and etc.

V (Vitrified)

Vitrified bond or Ceramic bond, which is a vitreous binding material. It brings excellent grinding ability and superior in forming.

E (Electroplated)

Electroplated bond shows high stock removal capability, stable performance in grinding accuracy and grinding ability.

Contact us

Contact us